Pareto Chart (Manufacturing Example)

The Pareto Chart is a tool used to rank the various categories/causes of a problem by charting them as bars in descending order of frequency or magnitude from left to right. It helps establish priorities by dividing the causes into the ‘vital few’ and the ‘trivial many’.

The theory behind the Pareto Chart originated in 1897 when an Italian economist named Vilfredo Pareto created a formula representing the uneven distribution of wealth - what later came to be known as the 80-20 rule.

You have probably heard a version of it like: "20% of the people cause 80% of the problems", or a derivative. Dr. J. M. Juran started applying this principal to defect analysis.

In fact, many (most) defect distributions follow a similar pattern, with a relatively small number of issues accounting for an overwhelming share of the defects.

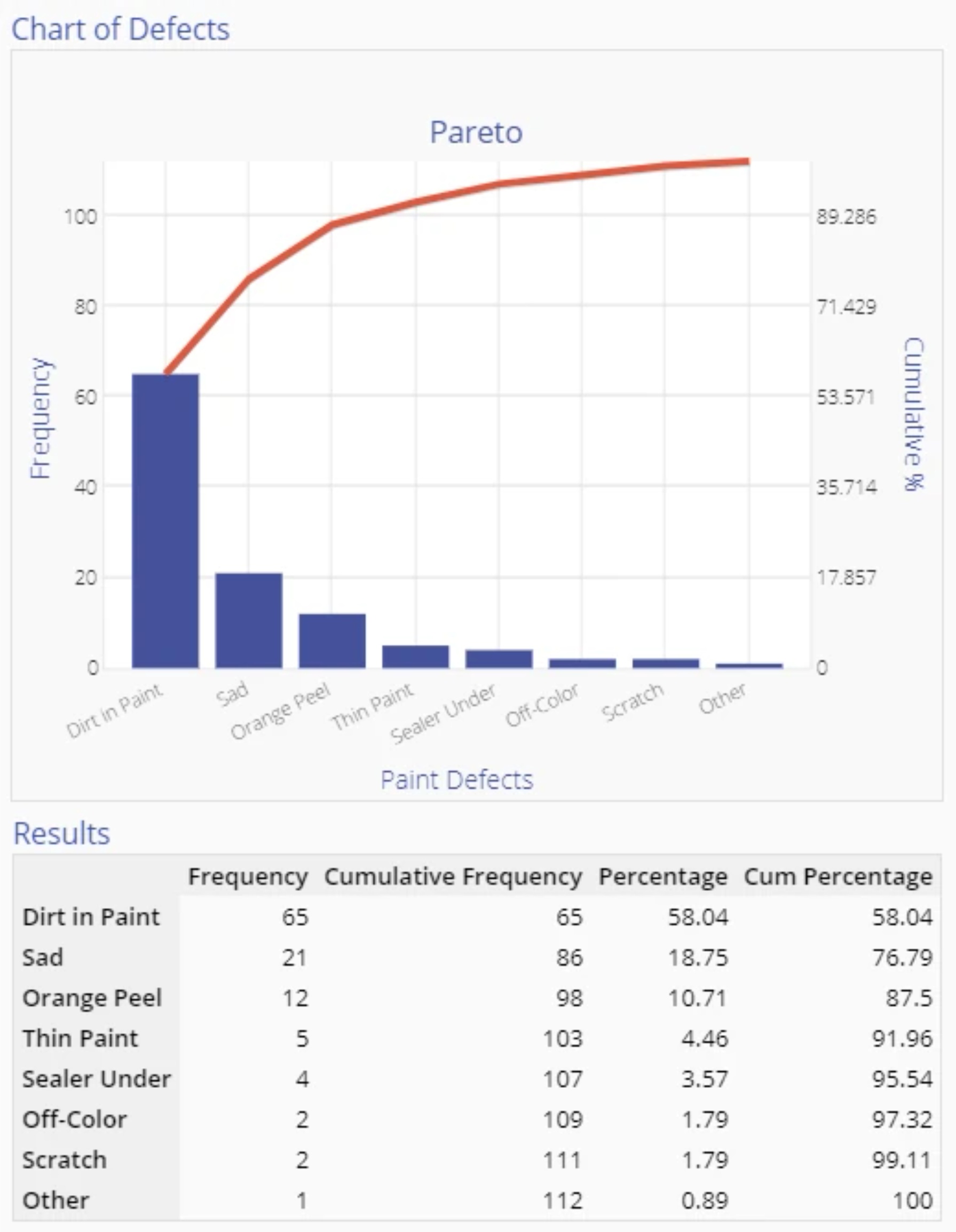

Following is an example of paint defects from an automotive assembly plant:

After reviewing the chart above, there is no question which defect to work on first. However, this Pareto Chart is constructed from one dimension only - defect frequency. If you learned that it costs $10 to fix a Dirt defect, while Sag defects cost $100 to correct, Sags would probably be the highest priority.

Likewise, if one category represents a constraint on the whole process, its priority would be elevated. You may wish to consult the Project Priority Calculator for a template to prioritize along multiple dimensions.

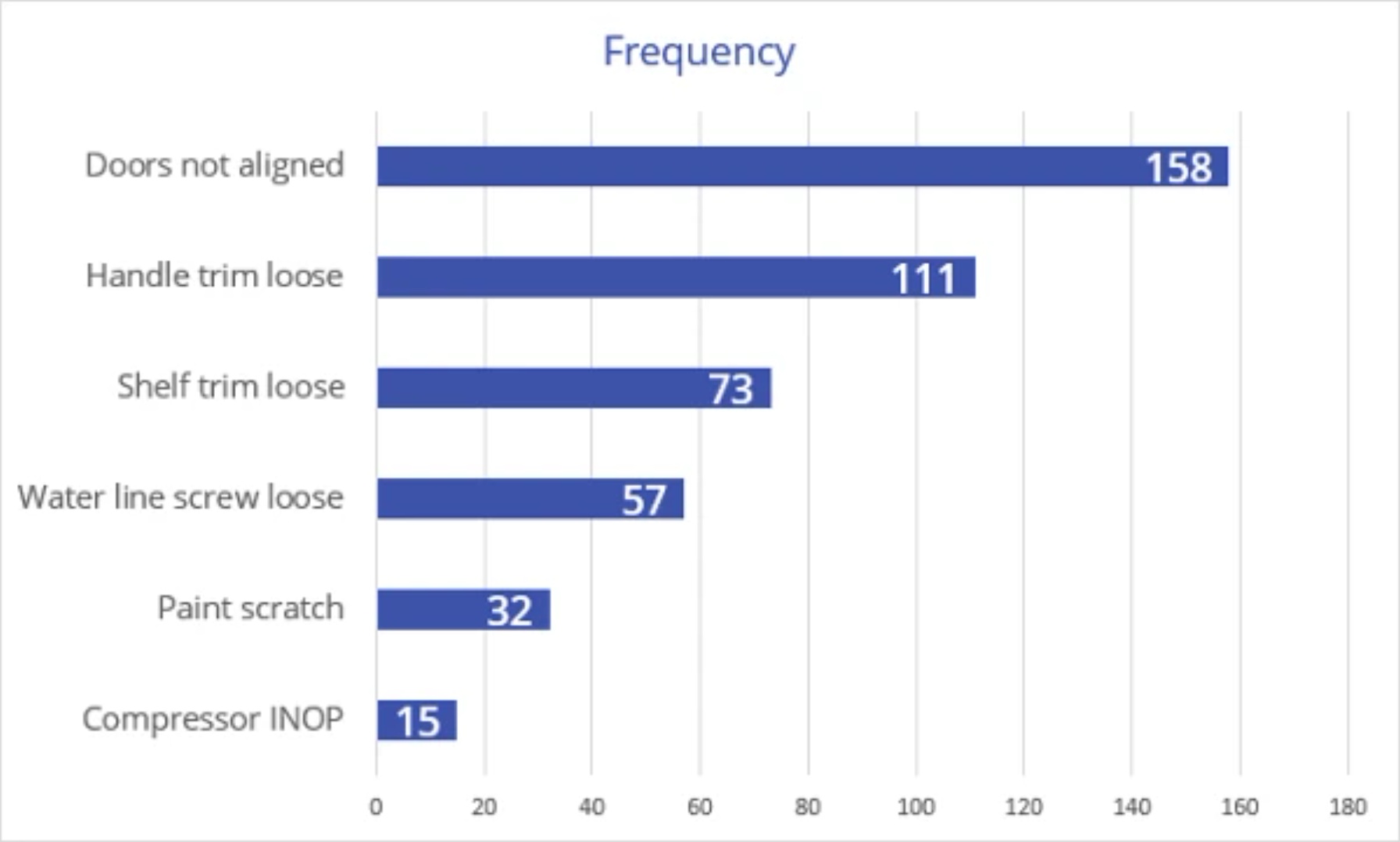

You can generate a Pareto Chart using virtually any spreadsheet or charting software. These charts were created using EngineRoom. Pareto charts are often constructed with horizontal bars, and without the cumulative percentage line, as shown below:

Choosing the Right Pareto Chart Software

Problems inside an organization can have many causes. As a result, it’s essential to identify the issues driving the largest share of them - and the difficulties whose fixes would have the greatest impact. EngineRoom’s Pareto Chart tool is an efficient and effective way to turn data on problem frequency into actionable insights on what to prioritize in the next steps of the problem-solving cycle.

EngineRoom’s Pareto Chart tool meets users where they are in the data-gathering process: Users can begin by inputting raw, unaggregated data or data already grouped into categories, along with the frequency at which a problem occurs. From there, they can add or remove critical variables like problem frequency or cost to correct through a user-friendly “drop zone.”

EngineRoom also allows users to customize the Pareto Chart by toggling a cumulative frequency line or allowing the tool to automatically group data after counting a certain percentage of observations. Ultimately, this quick process produces a results chart that will enable users to pinpoint high-value targets for future fixes. With EngineRoom’s Pareto Chart tool, the leap from raw data to clarity on the next steps is quick and simple.

Summary

The Pareto Chart is a simple to use and powerful graphic to identify where the majority of problems in a process are originating. Using a Pareto Chart early in problem solving is an effective strategy to decrease project complexity.