How to Use Six Sigma Simulations for Better Training Outcomes

April 3, 2025The Most Underrated Tool in Lean Six Sigma Training? Simulations.

Simulations are often the missing piece in Lean Six Sigma training, hidden in plain sight, yet incredibly powerful when integrated with intention. While most program leaders focus on eLearning and project work, simulations can bridge the gap between theory, real-world application, and on-the-job performance. Lean and Six Sigma Simulations build confidence, spark enthusiasm, and reveal if people have a true understanding of Lean Six Sigma concepts.

At MoreSteam, we’ve seen simulations transform training programs, not just once, but repeatedly across industries. If you're responsible for designing or delivering Lean Six Sigma training, it's time to consider simulation-based learning as a foundational strategy, not just a supplement.

Simulations Generate Enthusiasm and Confidence

When designing a training program, it pays to be intentional from the start. Adult learners arrive with high expectations and a healthy skepticism. They want to know the purpose of training, understand the process, and see a clear payoff. Simulations help deliver on all three.

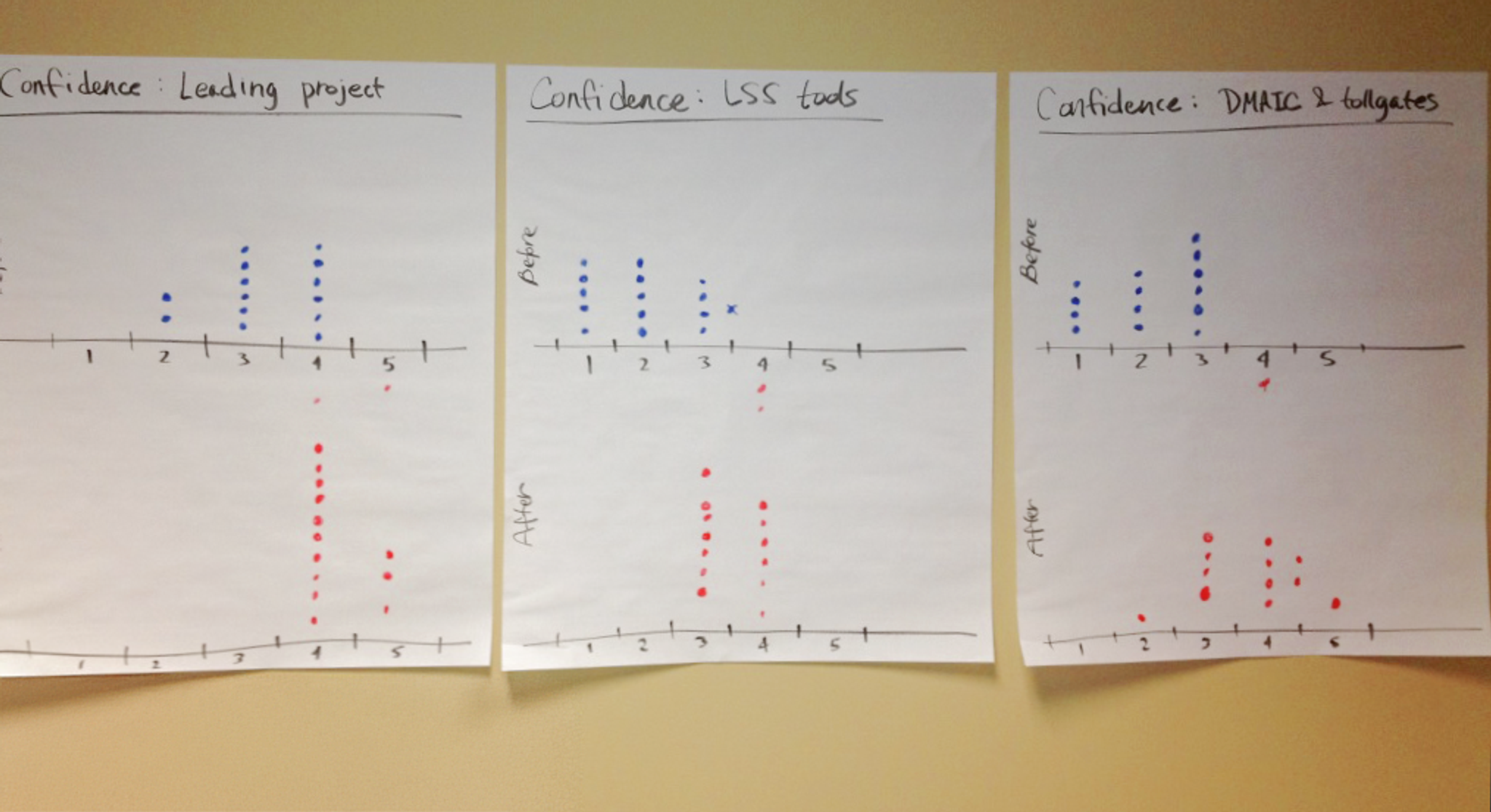

Running a simulation like Gridlock , a role-based Lean workflow simulation—on day one shows learners the "why" in action. We’ve used this kickoff approach with classrooms full of beginners, asking each participant to rate their confidence using Lean Six Sigma tools on a scale from 1 to 10 before and after the simulation. The shift in confidence is striking. Learner engagement deepens, and enthusiasm builds. Learners begin to believe they can apply Lean Six Sigma after participating in just one simulation.

Take a look at the flip charts below from a recent workshop, capturing the shift in confidence before and after the simulation:

Why does it work? Because adults don’t want to be lectured, they want to be engaged. A simulation provides a safe, structured environment to try, fail, reflect, and succeed. Programs that begin this way send a strong message: this is hands-on learning with real-world value.

While simulations are often used to generate enthusiasm and build confidence early on, they can also serve as an effective readiness check. In Constellation Energy’s Embedded Lean Practitioner Program, for example, simulations like InBox, a more intense, Kaizen-focused experience, and MoreSteam’s most popular simulation, can be used to assess who’s ready to move forward with Yellow Belt training.

Designing Study Halls with Gemba-Based Sims Builds Independent Thinking

As training progresses, the role of the instructor shifts, from a lecturer to a coach. This is where gemba-based simulations and threaded case studies become especially valuable.

Programs that incorporate study halls supported by gemba-based simulations like Fraud Squad or St. Sigma Hospital System, allow learners to explore processes on their own. Instructors move pod to pod around the room, offering help only when needed. It’s a subtle but powerful shift. Learners experiment with virtual processes, apply Lean Six Sigma tools, generate solutions, and get stuck, and instructors bridge the gap at just the right moment to help that growth take root. This structure gives learners the opportunity to work independently while still receiving personalized support.

Throughout the virtual gemba, participants walk through the DMAIC process by asking critical questions, developing analytical thinking, and understanding how tools are connected across phases. Instructors are supported with detailed facilitation guides, including questions, answers, and justifications.

The experience is also highly customizable. Instructors can tailor the pace, depth, and sequence of the content to meet learners where they are, whether that means walking entry-level participants through high-level concepts or challenging more advanced learners to think critically and dig deeper. The simulation platform even includes options for gamified play, creating an engaging and immersive environment for experimentation and skill-building.

Simulations create the ideal balance between structure and autonomy. They're challenging enough to push learners out of their comfort zone, yet designed to offer just the right level of support. This sweet spot is known as the Zone of Proximal Development, where learning is the most effective. Learners can do it, but only with the right guidance. Simulations provide that support, helping learners grow and build confidence until they’re able to perform independently. This is where learning, growth, and confidence truly begin.

And because instructors can observe how teams handle problem-solving challenges in real-time, they gain a clear picture of who’s ready to move forward to real-world improvement projects and who may need more support before advancing.

Simulations Prepare Learners for Real-World Impact

The best programs don’t just deliver training, they build capability. Simulations that follow or are integrated into training solidify a learner’s understanding of when and how to apply each tool. They close the gap between classroom learning and project execution by ending with a step-by-step simulated project or capstone project like Sherlock Holmes Zombie Hunter or SigmaBrew. These simulations help learners synthesize what they’ve learned and confidently apply it to real projects.

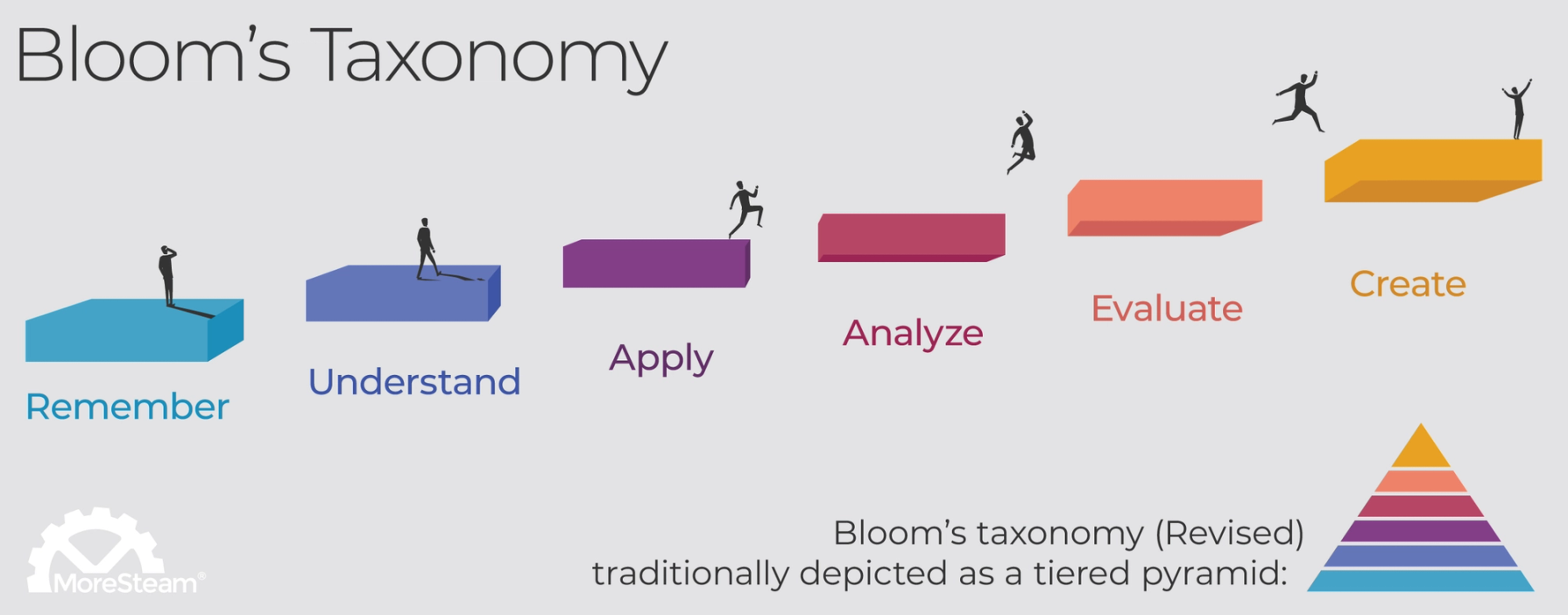

As an instructor, you cannot expect your students to successfully carry out an improvement project until the learning activities match the complexity of the skills you want them to develop. Learners can’t just be taught what the tools are; they need to practice applying them in environments that reflect real-world complexity. That’s where Bloom’s Taxonomy provides a helpful framework.

Think of learning as a progression:

- Remember & Understand: eLearning builds foundational knowledge

- Apply, Analyze, Evaluate: Simulations provide a space to practice and problem-solve

- Create: Learners are now ready to tackle real-world improvement projects

Mastery doesn’t happen at the base it’s earned at the top. In order to do hard things, learners need to practice hard things. Simulations provide the bridge from knowing to doing, giving learners the structured experience they need to climb from theory to confident, capable execution.

Running a full DMAIC simulation at the end of a program helps them connect learned concepts to practical application, boosting confidence, sharpening problem-solving, and giving trainers clear insight into project readiness. It’s the moment when learners either prove they’re ready to lead real improvement initiatives or identify where more support is needed.

This is where the responsibility of the program leader comes in. If your organization is looking to realize the full value of training, it's on you to build programs that develop capable problem-solvers, people who are prepared to lead change, not just understand tools. Lean and Six Sigma Simulations and Games are some of the most effective ways to do that, providing a safe, risk-free space to execute a full project and demonstrate readiness before stepping into a real one.

Simulations Are the Secret Sauce. Now Learn to Use Them

Too many training programs skip simulations and miss the chance to create real engagement, understanding, and skill. We believe simulations are the secret sauce behind the most effective Lean Six Sigma programs. They're not a bonus, they’re essential. And yet, many trainers don’t even know this powerful learning tool exists.

Simulation-embedded learning builds better programs, better teams, and better results. It builds confidence and independent thinking. It bridges the gap between training and real-world performance. Simulations give instructors the tools to build true capability, the kind that prepares learners to lead real improvement projects, create lasting value, and show up where it matters most: in the real world.

If you're a trainer, coach, or program leader, now is the time to take action. It’s your responsibility to ensure your learners leave not just informed but prepared to lead meaningful change. The organizations you serve are counting on you to deliver results and simulations are one of the most effective ways to make that happen.

Join us at SimCamp, a hands-on experience where we train facilitators to confidently run our full portfolio of Lean and Six Sigma simulations.

Prefer to explore first? Book a demo and see our simulations in action and discover which are best suited to your program's goals.

Realize the full potential of your training program. Tap into the value simulations can deliver. Your learners deserve it. Your organization needs it. And it starts with you.

Marketing and Business Development Specialist • MoreSteam

Lexi began working with MoreSteam’s Marketing team in August 2024. Since then, she has made a strong impact through email and social media marketing, content creation, and advertising efforts. She has also helped strengthen alignment between Marketing and Sales and now supports initiatives across both teams. Lexi earned both her undergraduate degree in Integrative Management and her MBA in Marketing and Analytics from Niagara University in just four years—all while competing as a collegiate volleyball athlete. She brings the same determination and adaptability from the court to her work, continuously expanding her skills and contributions.