Leaning, But Not Running, Toward Six Sigma

March 9, 2009Is Poor Quality, Delivered Quickly, Lean?

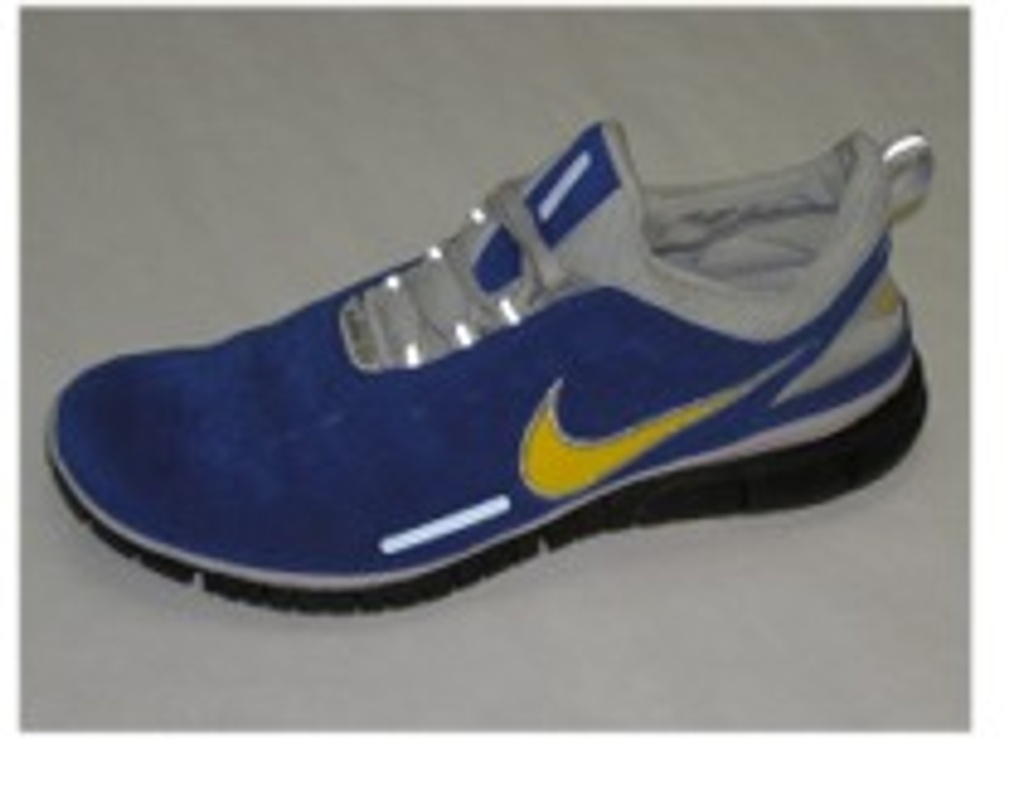

As the owner of a defective shoe, I recently ran into a perfect example of the interplay between Lean Methods and Six Sigma. A year ago, I bought a pair of the new Nike Free® running shoes. If you have not seen these, they are really cool. Ultra‐light, and extremely flexible, they are perfect to tuck into any empty space in your luggage without adding the extra weight and bulk normally associated with toting an extra pair of shoes on a trip. They were intended to simulate the feel of running in bare feet, an objective that was achieved. I liked them a lot.

But as with many favorite products, there was a dark side. Two months ago, I noticed that the nearly sheer fabric in the heel area had split horizontally, despite rather light usage and very little actual running mileage. I was surprised, but as we say, "Shift Happens." Now the story gets interesting...

I found the Nike Customer Service number on their website, called and managed to sort through the automated menu to the right interface after two tries. It was a totally automated system, which surprised me for a product return process, but it worked pretty well, I entered my name and address and was given a claim number and instructions for mailing my broken shoes to Oregon.

I was a bit skeptical, but I mailed my shoes off (in and old Adidas box, which seemed appropriate), not really expecting anything to happen quickly, if at all. To my surprise, in about a week I received a Product Certificate for $85 (the price of the shoes) to be redeemed at Nike.com. This is the start of the Lean part of the story. I was happy, partly because my expectations were pretty low.

Now the impressive Lean part starts. I went to the website and found that I could custom‐design my new shoes with virtually any combination of colors. I picked the ever‐popular MoreSteam blue and gold (not the preferred colors in my hometown of Columbus, OH, as any of you University of Michigan fans can testify). The website told me that I should expect to wait up to a couple of months for the shoes. I was disappointed at this time since the indicated lead time would leave me without my favorite shoes for the summer.

A few days after ordering the new shoes, I was in a shoe store again looking for shoes for my son. I asked the salesperson if he had seen other problems with the Nike Free® shoes. He told me that "probably 70% of them come back for split fabric." I asked, why are they still selling them? He replied, "Oh, they changed the design to make them stronger."

Then he showed me how the newer version 2.0 shoes are reinforced in the heel and along the sides. Then he added: "Except the Lance Armstrong model. It's still the old design." I asked "Why are they still selling a model that is known to be defective?" He shrugged and said, "They had a deal to have them in the stores for a certain period of time."

I was amazed. It's doubtful that the salesperson is privy to Nike policy discussions, but even discounting the story somewhat, I found it hard to believe that Lance Armstrong would want Nike to sell known defective shoes with his name on them. Curious.

This episode highlights a common shortcoming of the commonly applied DMAIC process, which doesn't put much or any emphasis on CONTAINMENT. In the Define Phase (or Measure), when if it is determined that defective product is being shipped, then actions must be taken to isolate the customer from defects (especially known high‐frequency design‐related defects) for the several months that it usually takes to work through a project and nail the root cause.

Granted, short‐term containment actions like extra manual inspection are less than iron‐clad, but serious efforts should be made to build a fence around defects to protect the customer. This is emphatically true when defects represent potential safety issues. The extra cost of containment can also be a powerful incentive to identify and implement permanent corrective actions. OK, now back to the story...

The following week, about 10 days from the time I sent my shoes to Oregon, I received the custom replacement pair that I designed online. Wow! This was unbelievable. And they were made in China. Now maybe the color‐combination that I specified just happened to be sitting in inventory, in size 13, but that seems unlikely. I thought, "This is a really lean process. A customer order over the internet, a lot size of one, and shipped to my door from China in 10 days." This was the high point of my experience.

Unfortunately, when I looked at the shoes, I noticed that none of the version 2.0 design improvements shown to me by the salesperson were evident on the new shoes. The new shoes were identical to the first pair that fell apart. Maybe Lean, but not exactly Six Sigma — sort of like what my old basketball coach used to say: "It doesn't do any good to steal the ball and then dribble it off your foot." At present, the shoes are undergoing extensive field testing on my feet — something that a company like Nike ought to be able to accomplish before releasing a new design! But that's another story. I'll post the results of my testing at a later date.

I really like the shoes. I hope they last for awhile. If not, at least the replacement process is Lean.

CEO • MoreSteam

MoreSteam is the brainchild of Bill Hathaway. Prior to founding MoreSteam in 2000, Bill spent 13 years in manufacturing, quality and operations management. After 10 years at Ford Motor Co., Hathaway then held executive level operations positions with Raytheon at Amana Home Appliances, and with Mansfield Plumbing Products.

Bill earned an undergraduate finance degree from the University of Notre Dame and graduate degree in business finance and operations from Northwestern University's Kellogg Graduate School of Management.